认 证:工商信息已核实

访问量:379413

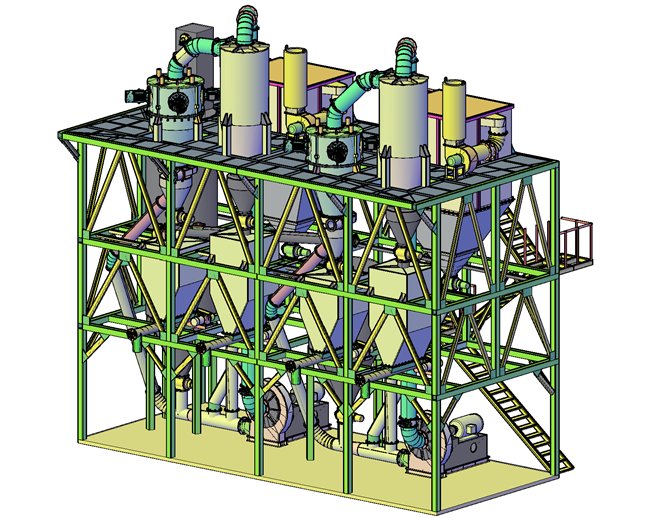

RFEF系列二次分级机

RFEF SERIES QUADRATIC CLASSIFIER

RFEF系列二次分级机,是营口瑞丰粉体设备有限公司采用成熟的分级技术,结合本公司生产配套的RFLM系列细粉立磨分级技术,解决目前普通分级机分级效果差、产量低等问题。本系列二次分级,可分选1.5~30μm,2μm含量可达90%。

RFEF series secondary classifier

RFEF SERIES QUADRATIC CLASSIFIER

RFEF series secondary classifier is Yingkou Ruifeng powder equipment co., Ltd. Adopts mature classification technology, combined with the matching RFLM series fine powder vertical mill classification technology produced by our company, To solve the current ordinary classifier classification effect is poor, low output and other problems. This series can be divided into 1.530 μ m ~ 2 μ m and can reach 90 μ m.

工作原理

进料螺旋输送机将储存于原料仓的粉体物料,用电脑控制以固定的流量进入进料管,而在进入分级机前,粉体物料会与风机的主气流充分混合,充满物料的主气流先进入分级机下部的蜗壳,运用蜗壳结构将进入蜗壳的气流改变运动方向,形成漩涡,在漩涡力的作用下,使进入下壳体的主气流变成螺旋上升气流,在离心力的作用下对粉体物料进行预分级,较粗颗粒粉体会先行分出,没有进入下壳体而从分级机底部落下的粗颗粒粉体,即为分级后的下品。

次气流则由下壳体的下方吸入,并且粗粉中再选出剩余的细粉。其余的含更细粉体的气流则被带入后分级区,分级出口装有3个或者多个分级轮的自动分级机进行选粉工作。粉体在此分级区中,收到离心力、流体阻力、以及自身的重力作用下,大于分级轮收束点的粉体则会被送回下壳体,小于收束点的粉体则随着气流带出分级机,风机将气体中的细粉自分级机带出,经脉冲式除尘器收集为成品,部分气体会从设备的排风管中排出进入大气,其余空气则被循环使用作为主气流,以维持整个分级系统可以正常运行。由脉冲式除尘器收集的细粉,及下壳体中的粗粉,会通过气力输送系统,根据其产品细度而运送到指定的不同的成品仓中,成品仓下方放置包装机进行包装。

Working principle the feed screw conveyer will store the powder material in the raw material bin, use the computer control to enter the feed tube with the fixed flow rate, and before entering the classifier, the powder material will be fully mixed with the main airflow of the fan. The main airflow filled with materials first enters the volute of the lower part of the classifier. The structure of the volute changes the movement direction of the flow into the volute and forms a whirlpool. Under the action of the whirlpool force, the main airflow entering the lower shell becomes a spiral upward flow. Under the action of centrifugal force, the coarse particle powder will be separated out first, and the coarse particle powder falling from the bottom of the classifier without entering the lower shell, that is, the coarse particle powder after the classification. The secondary air is inhaled from the bottom of the lower shell, and the remaining fine powder is selected from the coarse powder. The other airflow with finer powder was brought into the rear classification area, and the automatic classifier with three or more classifying wheels was installed at the outlet for powder sorting. In this classification region, when the centrifugal force, fluid resistance, and its own gravity are received, the powder larger than the bunching point of the classifier wheel will be sent back to the lower shell, and the powder smaller than the beam point will be brought out of the classifier with the flow of air. The fan takes the fine powder in the gas out of the classifier, and the meridian pulse scrubber is collected as the finished product. Some of the gas will be discharged into the atmosphere from the exhaust pipe of the equipment, and the rest of the air will be recycled as the main airflow. To maintain the entire grading system to work properly. The fine powder collected by the pulse dust collector and the coarse powder in the lower shell are transported to different finished product warehouses according to the fineness of the product through the pneumatic conveying system, and the packaging machine is placed under the finished product bin.

性能优势

1. 均匀的粒径分布。可根据所要求的收束点,调节控制,保持很窄的粒径分布。

2. 产品稳定,连续可靠。通过变频调节分级轮转速或调节风阀开度可任意调节产品细度,产品品种的调节方便简单,连续稳定。

3. 可大规模工业化分级生产,采用强力涡流分级设计,分级叶轮水平放置,多分级轮机构设计,更加适合400-8000目微粉大规模工业化分级生产。

4. 可设立独立的分级系统,单独使用。适合直连各类磨粉设备(如超细立磨机、球磨机、振动磨、气流磨、冲击磨、搅拌磨等),联合组成闭路连续超细粉体生产系统。

5. 全套分级系统,均采用PLC触屏智能化控制,可实现实时显示,参数、指标、温度、产量、细度等,并可做到可调可控。由于我公司技术成熟,可实现与RFLM系列超细立磨机**衔接,也可独立成为一套中控系统。

Performance advantage

1. Uniform particle size distribution. According to the required collection point, the control can be adjusted to maintain a narrow particle size distribution.

2. The product is stable, continuous and reliable. The product fineness can be adjusted arbitrarily by adjusting the speed of the classifier wheel or the opening degree of the air valve by frequency conversion. The adjustment of the product variety is convenient and simple, and the product is continuous and stable.

3. It can be used for large-scale industrial grading production. It is more suitable for large-scale industrial classification production of 400-8000 mesh micro-powder by using powerful eddy current classification design, horizontal placement of classifying impeller, and design of multi-classifying wheel mechanism.

4. A separate grading system can be set up for separate use. Suitable for all kinds of grinding equipment (such as superfine vertical mill, ball mill, vibration mill, airflow mill, impact mill, agitation mill, etc.) and combine to form closed circuit continuous ultrafine powder production system.

5. The whole classification system adopts PLC touch screen intelligent control, which can realize real-time display, parameter, index, temperature, output, fineness and so on, and can be adjustable and controllable. Because of the mature technology of our company, we can realize perfect connection with RFLM series superfine vertical mill, and can also become a set of central control system independently.

- 推荐产品

- 供应产品

- 产品分类